Picking back up on a much earlier post, I finally started casting my concrete arch hydrocal bridge in two halves.

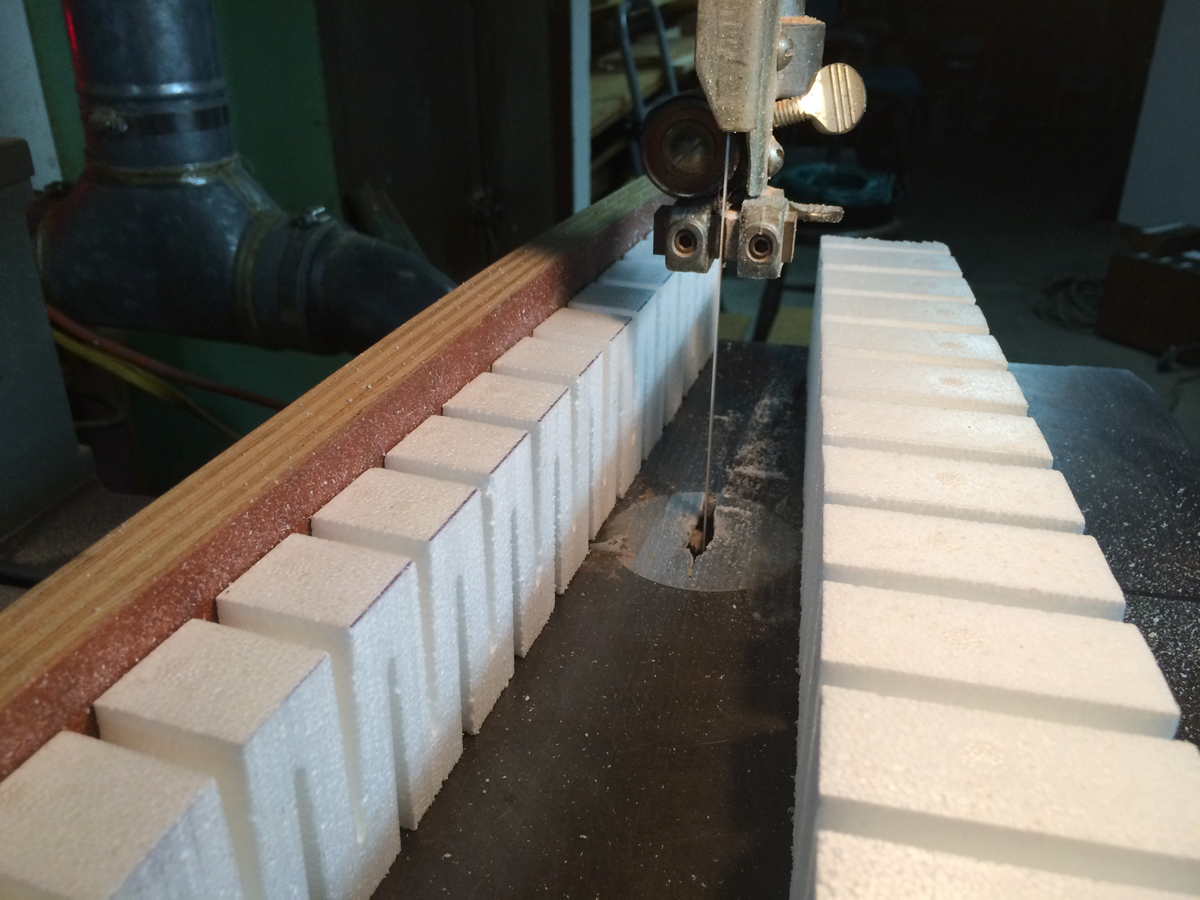

Wood & Sintra Mold

My waxed wood and sintra casting form

Wood & Sintra mold showing thickness

Pouring hydrocal with steel rod reinforcements

Pouring requires working quickly as Hydrocal sets fast

Leveling to the face of the form

Level as close to flat as possible

Exterior pieces of the form being removed

Exterior parts remove easily

Casting removed from the mold and flipped over, with only the individual small arch pieces to be removed. These pieces have a 3 degree slope for ease of getting them out of the piece. Still required a few knocks with a small hammer on each to remove!

Casting lightly sanded at this point

First half cast, but I’ll add some detailing with a file, forming casting joints and other details, then cast the other half and place them back to back, with a spacer which is typical for this type of bridge, really two identical arches, connected at the top.

Casting before final detailing