Visiting friends in Colorado, I was able to further my ongoing summer visits to full scale and model railroad sites. First was the Colorado Model Railroad Museum in Greeley CO, and then the Buenavista model railroad society in Buena Vista CO, both of which I will put up further posts in the near future, but the real unexpected treat was a tour of the

Intermountain Railway Co. the model railroad manufacturer in Longmont CO. Kirk was very gracious in showing the whole operation, from their milling the molds for injection molded parts on their CNC milling machines

CNC milling machine

Small detail parts half mold

Just a few of the many machined molds for various products

To explaining their process and inventory.

Small part of inventory

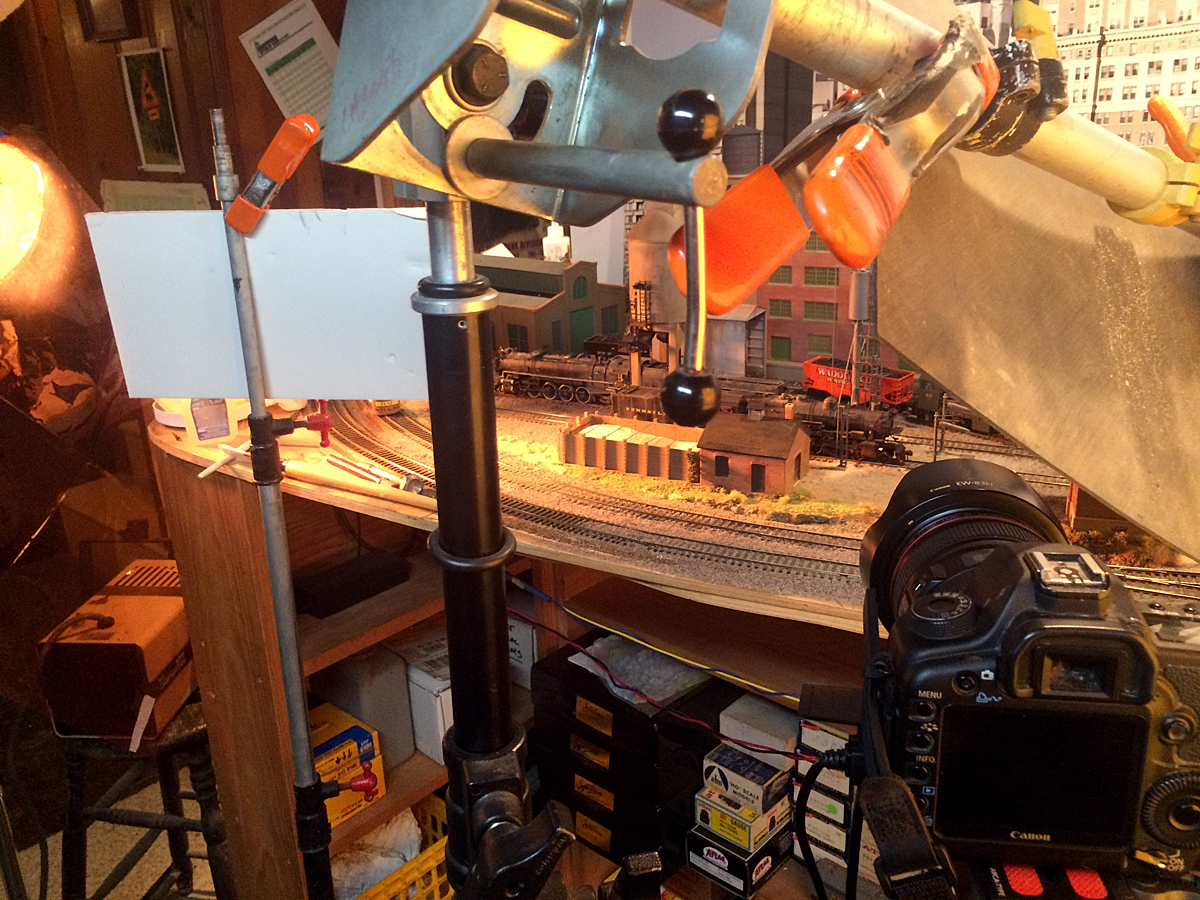

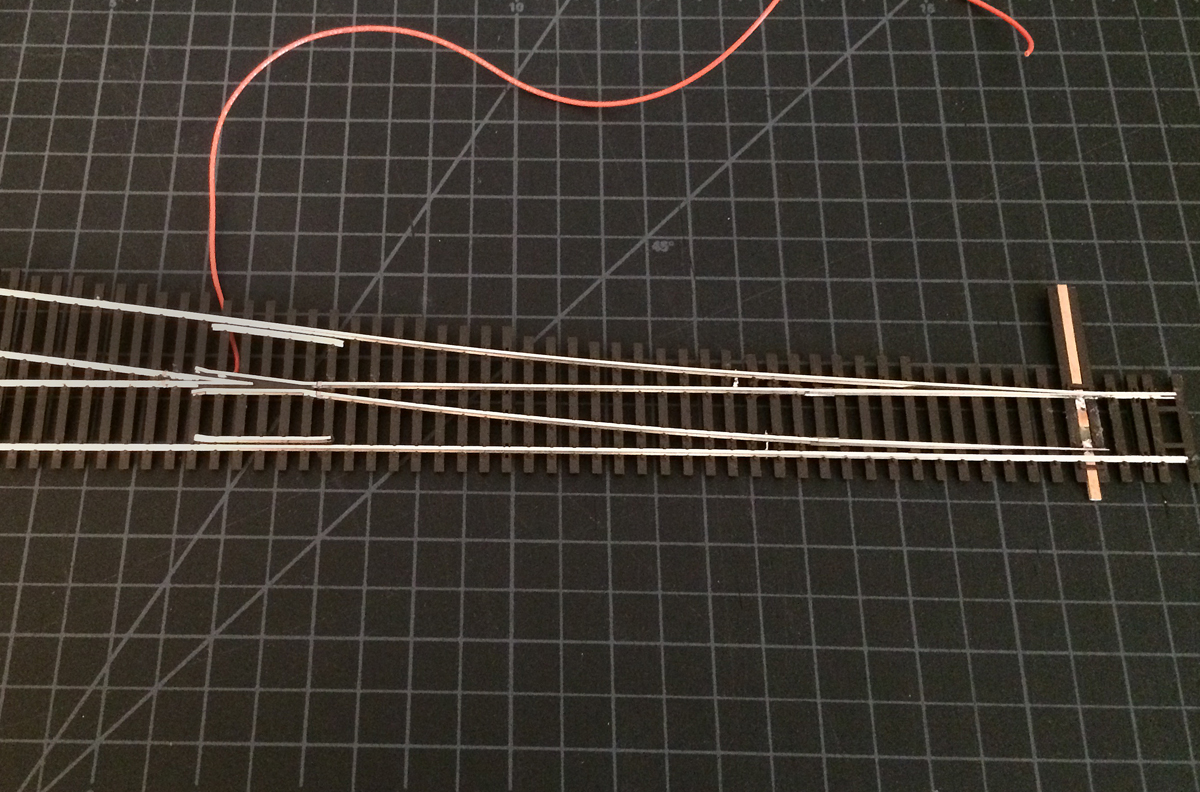

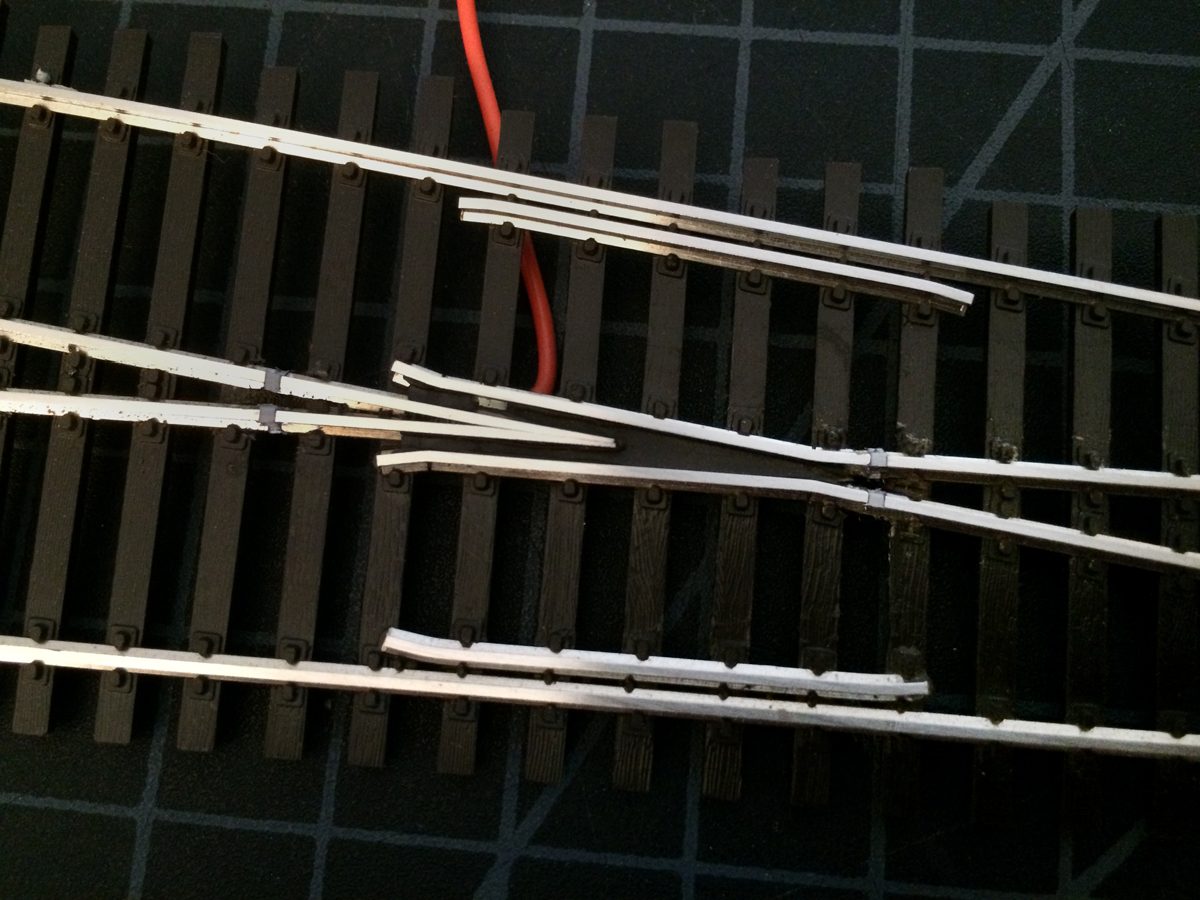

To talking about their quality control, including a final visual inspection of each and every HO engine and actually running each engine through various track situations. A very impressive commitment to quality, and not releasing anything that is not absolutely right.

Engines ready for inspection

engines in the inspection area

All in all an enjoyable morning and an appreciation of a quality company